Share to

Dragonbar™ FRP Reinforcing Rebar (Fibreglass Reinforced Polymer Bars / GFRP Reinforing Rebar) are manufactured by pultrusion process and our new machining technology.Their mechanical properties and bond properties are very excellent compare with the steel rebar.And they have very good in corrosion environments and the design service life can reach 100 years.

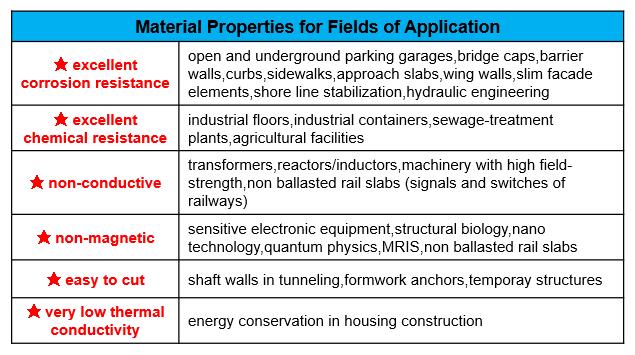

The main content material are fiberglass reinforced materials and high properties resin.Therefore,the rebar show excellent properties to these following fields of applications:

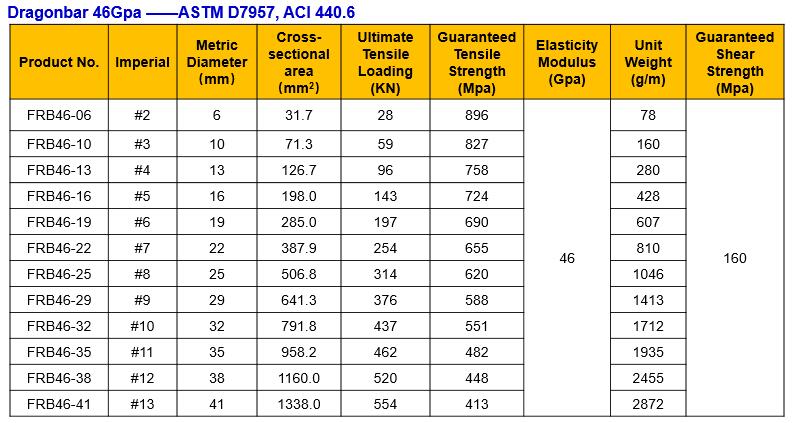

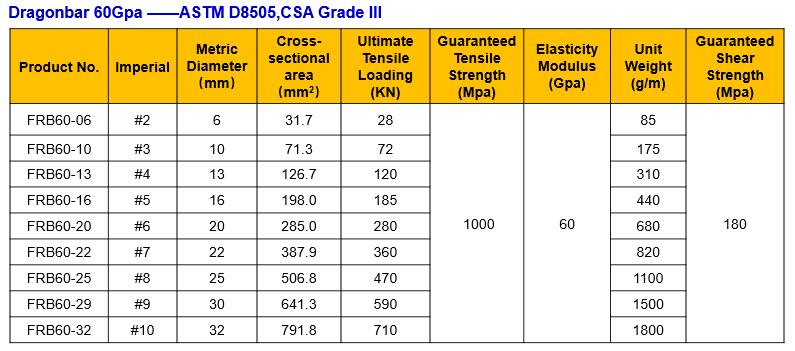

Technical Data

Applications:

Barrier Wall;Roads;Bridges&Tunnels;Electrical Isolation;Marine Engineering;Water Fronts;Water Treatment Plants;MRI Rooms, etc.

DESIGN GUIDES AND CODES

FRP rebar do not follow the design code of steel rebar because the mechnical properties are different in some cases. FRP rebar has higher tensile strength but lower elasticity modulus compared to steel rebar. Therefore,we can not direct replacement of the design code of steel when using FRP rebar in projects.So some councils in some country have drawn up some codes for FRP rebar to engineers for reference.

Canada

CAN/CSA-S6 Canadian Highway Bridge Design Code

CAN/CSA-S806 Design and Construction of Building Components with Fibre-Reinforced Polymers

CAN/CSA S807 Specifications for Fibre Reinforced Polymers

ISIS

Design Manual NO.3 Reinforcing Concrete Structures with Fibre Reinforced Polymers

Design Manual NO.5 Prestressing concrete structure with FRP

USA

ACI 440.1R Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars

ACI 440R Report on Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures

ACI 440.5 Specification for Construction with Fiber-Reinforced Polymer Reinforcing Bars

ACI 440.6 Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement(Reapproved 2017)

AASHTO GFRP-1 LRFD Bridge Design Guide Specifications for GFRP-Reinforced Concrete Bridge Decks and Traffic Railings