2021-09-06

Fiberglass form ties have the characteristics of corrosion resistance, no magnetic interference, light weight and high strength, which meet the new requirements of the construction of smart ports, intercity high-speed rail, 5G project and other new infrastructure.

2023-08-03

According to the relevant meteorological records, El Nino will directly cause high temperature, drought, rain and other catastrophic extreme weather and climate events in the tropical Pacific Ocean and its vicinity, and the application of new materials such as FRP building products and composite fasteners can greatly alleviate the impact of El Nino on human beings.

2022-07-19

Under the influence of various factors such as the intensification of the conflict between Russia and Ukraine, the escalation of sanctions against Russia by the European Union and the United States, and the harsh climate, the worldwide energy crisis has further intensified. The fiberglass rebar and fiberglass building products produced by our company can effectively alleviate this trend.

2021-12-02

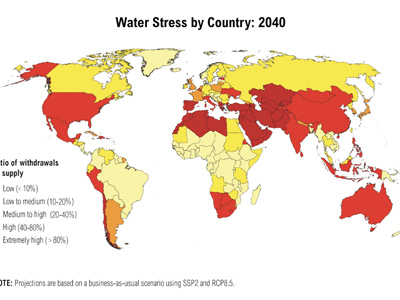

In the 21st century, water resource has gradually become a strategic resource, which plays a vital role in the survival and development of human beings. The scarcity of water resources forces human beings to take various measures to ensure the sustainable development of water resources.

2024-01-02

With the increasingly severe problem of global climate change, how to achieve the "global climate goals" set by the “Paris Agreement”as soon as possible has become one of the major issues that all countries in the world urgently need to promote, and the early realization of energy transformation has become a major consensus reached by countries around the world. Continuous green and low-...

2022-02-10

On February 4, 2022, on the fourth day of the first lunar month of the Chinese Lunar New Year, when the new crown epidemic has ravaged the world for more than two years, the much-anticipated 24th Winter Olympics officially opened at the Beijing National Stadium (Bird's Nest). The concept of this Winter Olympics is "green, shared, open, and clean", and green is the primary goal, which is closely related to what our current party and government have been paying attention to and actively and effectively promoting the "dual carbon" process. In the construction process of Olympic venue facilities, insisting on energy conservation and recycling is the core, especially in the low temperature and humid environment in winter, the application of FRP products is a better way, such as the use of insulation connectors in building walls, glass fiber reinforcement, FRP outdoor guardrail, step anti-slip device, sewage treatment and underground pipelines.

As we all know, rain and snow weather, especially cold winter, is a very important test for the life cycle and cost of products and even life safety for the use of a large number of metal products in infrastructure construction. In winter, the metal surface often forms "frozen icicles", which is not only a huge test for the bearing strength of the product, but also easily causes unnecessary harm to people. In areas such as airport runways and highway tunnels, the use of metal products is not only due to the magnetic properties of metal can cause signal interference to electronic equipment, threatening travel safety, and long-term rain, snow and humid weather may also cause landslides and cause serious loss of life and property.

Under the background of the era of "strive to achieve carbon peak by 2030 and carbon neutrality by 2060", how to build and maintain our massive infrastructure in the safest and most economical way is not only related to people's lives and property security and vital interests are even more important to our smooth realization of the great national rejuvenation. The ninth meeting of the Central Finance and Economics Committee emphasized that the promotion of major breakthroughs in green and low-carbon technologies and the deployment of research on low-carbon cutting-edge technologies has highlighted the important supporting role of technological innovation in achieving carbon peaks and carbon neutrality.

FRP products series developed by Nanjing Sedray Industries Co., Ltd. in line with the requirements of the times -- Dragonbar™ fiberglass rebar& form tie, Dragonpro™ fiberglass building products (including:(1) standard structural profiles, (2) FRP handrail systems, (3) FRP decks & floors, (4) FRP gratings and accessories), Dragonstrut™ fiberglass framing system (fiberglass support system) (including:(1) FRP Strut Channels, (2)FRP Channel Fittings, (3)Fiberglass Threaded Rods,(4)FRP Hex Flange Nuts,(5)FRP Channel Washers, (6)FRP Molded Hex Flange Bolts,(7)FRP Assembled Hex Flange Bolts,(8)FRP Hex Nuts,(9)FRP Threaded Rod Couplers,(10)FRP Standard Channel Nuts,(11)FRP Molded Beam Clamps,(12)FRP Fabricated Beam Clamps, (13)FRP Fabricated Clevis Hangers) , can better reduce this unnecessary loss. These products mainly use high performance reinforced glass fiber and corrosion resistant resin and necessary additives, through the pultrusion process and special processing technology to produce, compared with traditional materials (steel, aluminum, stainless steel, plastic), has a very obvious advantage:

1. Corrosion Resistance: FRP/GFRP products will never corrode, rust or lead to concrete spalling in the concrete structure;

2. High Chemical Resistance: wastewater treatment, water treatment and desalination plants exposed to chemicals, water or high salt content of the environment, FRP/GFRP products can be very good resistance to the corrosion of the harsh environment;

3. Long Life Cycle: FRP/GFRP products are very durable, therefore, can reduce later maintenance and upgrade costs;

4. High Bending Modulus: the bending modulus of FRP/GFRP products is higher than that of thermoplastics, which is the ideal characteristic of the key components used for wastewater aeration. It can move in the water treatment process with a relatively low bending degree in response to any high bending load requirements in the water;

5. Low Moisture Absorption: unlike many plastics, the moisture absorption of FRP products is very low, even if it is soaked in water for a long time, there will be no obvious size change or mechanical property loss.